"I am good at building machines and I have delivered them for a long time and to a lot of customers. I want to monetize this know-how by adding digital services and business."

Why is it so important to have an IoT

solution?

For OEMs it enables new digital business and service layers.

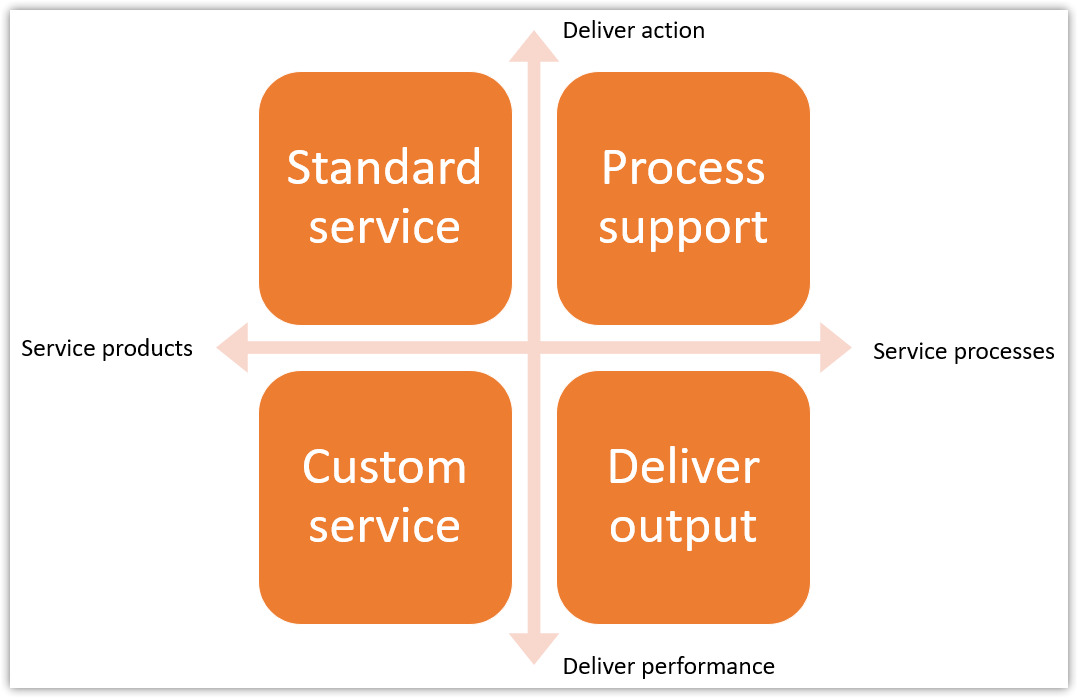

OEM Deliver Service Options

Standard service

Standard service is based on service contract. It is mostly about maintenance and spare parts. Time and content of service actions are agreed beforehand. The contract usually also includes extra actions, for example unexpected maintenance due to problems that have been discovered during operating or maintenance. The service is based on OEMs' excellent knowledge of their machines which enables them to plan the service operations for whole product's lifecycle. Benefits of the service include good predictability of service actions and not requiring real-time monitoring of the machine. Challenge is that the risk of unpredicted operating problems increases and it may cause downtime and costs.

Custom service

Custom service also includes beforehand agreed actions but it is more reliable when it comes to predictive maintenance. Instead of doing maintenance based on plan and clearly visible wear and tear, other issues can be detected way before they start affecting performance. If the machine can be monitored in real-time or low latency it can be used to manage service actions. If some critical limit is exceeded it can be alerted which can then be used to trigger and supervise a service request. With reporting it is also easier to show the actual value of service actions. Customized service model is about truly delivering uptime, not just spare parts and maintenance.

Process support

Process support services assist and and enhance client's business processes. It can simply be about reporting machine performance details to client's operators, service personnel, production planners or management. Having such visibility will improve the business processes. More evolved ways of improvement are optimizations by AI and machine learning, digital twins and edge computing. It is possible to more accurately show manufacturing details or phases of the clients product similar to new car manufacturing. If the clients agree to you can provide a community based learning models to improve operator skills etc.

Deliver output

Despite the level of service the clients usually have to buy the machine. But they don't actually want your machine, they want its output. One way to solve this is to lease the machine. The client avoids a big upfront investment and the maintenance is included. The next step is to sell the output. It can be quite challenging. You really need to know your machine and what it does well plus you need to have real-time monitoring. Also pricing will take some considerable thinking. But once you solve the challenges the output model can be an extremely desirable solution for your clients and can be a disruptive game- changer for your industry.